Solutions

Machinery

Series 300

Type 302

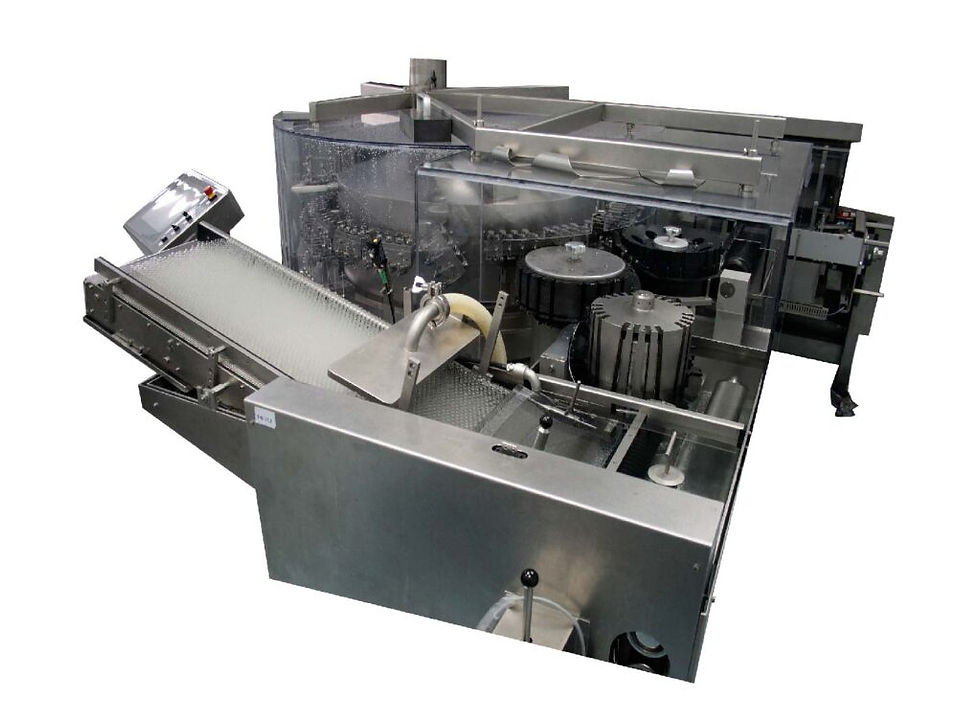

The Type 302 is a rotary washing system designed for cleaning ampoules, bottles, cartridges, vials, and various other containers.

Key Features

- Outputs up to 24,000 containers per hour

- Smooth container handling with coated grippers

- Infeed options from trays or an upstream machine

- Available ultrasonic bath and recycling station

- Optional water heating up to 85°C / 185°F

Type 303/304/305

The Type 303/304/305 machines are designed to wash vials, syringes, cartridges, and ampoules. They clean and dry both the inside and outside of the containers, achieving up to a 3-log reduction in contaminants.

Key Features

- Outputs up to 9,000 containers per hour

- Constructed from high-grade stainless steel and

pharmaceutical-grade plastics

- Smooth container handling with coated grippers

- Optional cost-effective WFI recycling unit

- Compatibility with various cleaning agents

- Energy-efficient cleaning needle design

- Needle movement ensures thorough cleaning of the

entire container interior

- No glass-to-glass contact during cleaning cycles

- Optional siliconization with servo-controlled needle

movement for customized silicone patterns

Type 306

The Type 306 is a semi-automatic washing machine designed for smaller scale operations, suitable for ampoules, vials, syringes, bottles, and cartridges.

Key Features

- Outputs up to 1,500 containers per hour

- Manual loading

- Cleans the inside and outside of the containers

- Quick size changes

- Intermittent spray of media synchronizes with the

transport system

- Up to 12 stations with 3 different cleaning media

- Optional recycling station

Type 308

The Type 308 is a high-speed machine designed to wash ampoules, cartridges, syringes, and vials. Featuring an innovative balcony design, it allows operators to maintain visual contact with the process. Fully customizable, it offers modules for inside and outside cleaning, inner and outer blow drying, siliconizing, tip cap or needle shield application, and the use of various cleaning agents.

Key Features

- Outputs up to 36,000 containers per hour

- Containers are fed automatically from an upstream

machine or manually from trays

- Ultrasonic bath for pre-cleaning of the objects

- No glass-to-glass contact using coated container

grippers

- Specialized cleaning needles designed to improve

energy efficiency

- Servo motors positioned along the line guarantee the

alignment of the containers with the washing and

drying needles

Type 309

The Type 309 machine is a fully automatic, continuous washing system designed for the external cleaning of ampoules, vials, and bottles. It washes, rinses, and dries the external surfaces of the containers, which are then discharged into trays or sent to downstream processing.

Key Features

- Outputs up to 21,000 containers per hour

- Flexible and compact design allows for customized

cleaning cycles

- Easy access to the cleaning stations and for size

changes

- Quick and easy size changeovers to process container

sizes up to 95 mm in diameter and 180 mm in height

- Specialized cleaning needles designed for ideal results

and improved energy efficiency

- Sterile hot air blow drying parameters are adjustable

via the operator interface terminal

- Optional recycling station, Type 705, provides cost

efficient reconditioning of used cleaning agents

Series 400

Type 401-40X

The Type 400 series machines offer hot air sterilization for glass ampoules, vials, syringes, and cartridges. The depyrogenation process is divided into three main zones: 1) Pre-Heating, 2) Depyrogenation, and 3) Cooling. These machines can be seamlessly integrated into downstream processing.

Key Features

- Outputs up to 610 kg per hour

- Air convection pre-heating and sterilizing zone for

energy efficiency and gentle heating of the containers

- Containers are fed automatically from an upstream

machine or manually using trays

- Temperature and differential pressure indicators

ensure ideal and repeatable machine settings

- Temperature distribution is achieved by multiple

control sensors

- PLC for system control and monitoring of relevant data

- Servo-controlled baffles aid in cross-flow regulation

Type 411

The Type 411, Puv-A-Tech™, is an enclosed sterile transfer chamber utilizing pulsed ultraviolet radiation light to decontaminate outer surfaces. This technology achieves up to a 6-log reduction within 5-30 seconds of exposure time.

Key Features

- Machine designed as a pass-through into a cleanroom

or isolator

- Components are placed into the chamber by an

operator or robotic arm, and the door is closed to

contain the process

- Complete cycle (loading, exposure, and unloading)

decontaminates the entire interior of the unit and

container surfaces within 20-60 seconds

- Components are removed and ready for the next

processing stage

- 100% verification on every cycle

- Available as a stand-alone or in-line machine

Series 500

Type 502/503

The Type 502/503 machines combine the filling and closing of ampoules into one single compact unit.

Key Features

- Outputs up to 6,000 containers per hour

- A transport star wheel provides smooth and

continuous transfer of the objects to the working

stations

- Two-piece, valveless dosing pumps provide precise

dosing with filling accuracy up to +/- 0.05%

- The containers are continually rotated to minimize

foaming of the product and ensure an evenly heated

ampoule stem, leaving a perfect dome

- Vials are closed with rubber stoppers, fed from a

vibrating bowl

- Optimized for use under laminar flow, RABS, or isolator

- The machines can be used as stand-alone units or

integrated into a production line

Type 504-506

The Type 504/505/506 machines are designed for filling and closing both open and pre-sealed ampoules. Their design enables quick and easy changeover from ampoules to vials.

Key Features

- Outputs up to 24,000 containers per hour

- Rotary-style machine provides smooth and gentle

continuous transport of the objects

- System control via PLC

- User-friendly touch screen operation

- Rotation of the object minimizes foaming of the

product and ensures an evenly heated ampoule stem,

leaving a perfect dome

Type 515

The Type 515 is a filling and closing machine designed for vials and syringes. Optimized for use under laminar flow and constructed from high-grade stainless steel, this machine ensures optimum hygienic performance.

Key Features

- Outputs up to 3,600 containers per hour

- Liquid filling

- Highly flexible and compact design

- Containers are transported into a star wheel that

moves them to different processing stations

- Filling needles are controlled by a servo drive for fast

and accurate dosing

- Ultra-high filling accuracy

- Stoppering is fed through a sorting bowl, picked up by

a vacuum tool, and precisely inserted

- Few size parts, quick changeover from vials to syringes

- Integrated inspection system

- Laminar flow and/or isolator friendly design

- Can be used as a stand-alone machine or integrated

into a complete processing line

Type 515 Plunger Rod Assembly

The Type 515 combines high-speed plunger rod insertion and labeling of syringes in a single unit. At the heart of the machine is an automated transport star wheel that moves products through four different stations, enabling the assembly of up to 40 syringes per minute. At the first station, a pneumatically actuated gripper assembly picks up a plunger rod from the end of the vibratory track and uses a 2-axis robotic arm to thread it into a syringe. At the second station, backstops are carefully placed on the flange of each syringe. The third and fourth stations check for the presence of the plunger rod and backstop.

Key Features

- Outputs up to 2,400 syringes per hour

- Compact machine design with integrated control

cabinet

- High precision plunger rod insertion

- Monitored torque for ideal closing results

- Camera inspection checks for proper plunger rod and

backstop placement

- Optional labeling station available

Type 529

The Type 529 semi-automatic filling and closing machine for flexible bags sets new standards in the pharmaceutical market. It is capable of processing all bag types (EVA, PVC, PP) with fill volumes ranging from 50 mL to 5 L.

Key Features

- Available in tabletop, dual, semi-automated conveyor,

and fully automatic versions

- Ideal for lab trials (1 filling head) and production (2-4

filling heads)

- Peristaltic or mass flow filling method options

- Attached flow regulator for high filling accuracy

- Automatically cuts pre-sealed tubes for filling

- Stoppering and heat/RF/ultrasonic sealing

- Manual or conveyor belt transport system

- Integrated closing system eliminates product

contamination

- Compatible with Laminar Flow and light curtain

systems

Type 534

The Type 534 is an automated filling and closing machine designed for vials, bottles, and other free-standing containers. Its modular design allows for easy customization to meet specific customer requirements.

Key Features

- Outputs up to 9,000 containers per hour

- Good accessibility to all workstations with inline design

- Adjustable walking beam transport for different

container sizes

- Servo-controlled filling needles for precise filling

tolerance up to +/- 0.05%

- Up to 100% in-process control verification

- Sorting bowls for closures such as stoppers and caps

- Vacuum-activated placement of stoppers into vials

- Torque-monitored crimp capping

- Separate container reject and discharge lanes

- Compatible with RABS, Laminar Flow, and/or isolator

systems

Type 535

The Type 535 machine is designed to fill and close nested vials, syringes, and other nested containers. It is the ideal solution for manufacturers seeking to automate and/or validate the filling of products in clinical trials or during the development phase.

Key Features

- Outputs up to 4,600 containers per hour

- Manual nest loading and unloading

- Turn table in-feed and out-feed

- Rotary piston pump, peristaltic pump, or time pressure

filling options

- 6-Axis clean room robot or X-Y transport system

- Sorting bowls for closures

- Filling and closing under vacuum to reduce

contamination and bubble formation

- Compact machine design with integrated Laminar Flow

- Machine guarding for optimum user safety

Type 543

The Type 543 filling and closing machine is designed to process vials, syringes, and cartridges with either intermittent or continuous motion throughout the machine. Its modular design allows for easy adaptation to customer-specific requirements.

Key Features

- Outputs up to 10,000 containers per hour

- Rotary piston pump, peristaltic pump, or time-pressure

dosing options

- Customized stoppering station with vacuum assist

- Direct in-line verification with camera system

- All parts in contact with the product can be easily

disassembled and sterilized

- Quick and easy size changeovers

- Containers are transported separately in individual

holders, which can be quickly changed for different

size containers

Type 550

The Type 550 machine features a high-speed, continuous motion balcony design for the filling and closing of vials and cartridges. Its servo drive technology ensures maximum versatility and repeatability.

Key Features

- Outputs up to 36,000 containers per hour

- Processes standard and freeze-dried rubber stoppers

- Best suited for through-the-wall installations

- Adjustable main transport system for quick and easy

size changeovers

- Containers are separated and individually fed to the

main transport system

- Optional pre- and post-gassing available

- Integrated inspection system to reject faulty

containers

- Precision force control for crimping and integrated

visual inspection system ensures proper sealing

- Balcony design provides optimized laminar flow

friendly operation inside a Class A clean room and can

be directly combined with an isolator or a rapid access

barrier system (RABS)

Type 570

The Type 570, Vers-A-Tech™ is a semi- or fully-automatic machine designed to accelerate the packaging of Cell & Gene Therapy products, handling both bags and nested containers on a single platform.

Key Features

- Flexible pick & place modular platform

- Automatic robot technology for all processing

- Compatible with isolator and/or laminar flow systems

- Compatible with lyophilization transfer chambers

- Robot fills and stoppers nested containers

- Filling by peristaltic pump with disposable fill kits

- Custom nest holder for easy transfer of nested

containers in and out of the processing system

- Robot picks up a bag, inserts the open tube into the

filling needle, and then seals the tube

Series 600

Type 601/602

The Type 601-602 machines are compact, fully automatic systems designed for printing and applying self-adhesive labels to vials, bottles, syringes, ampoules, and cartridges. These continuous motion labelers can be integrated into a production line or operated as stand-alone machines.

Key Features

- Outputs up to 24,000 containers per hour

- Containers are automatically fed from an upstream

machine or manually using trays

- Individual transport of containers to the labeling

station by a star wheel

- Transport wheel designed with pockets for safe and

gentle handling of containers

- Precision servo control label dispenser for self

adhesive labels

- Label dispenser is adjustable for different sizes

- Label dispenser is controlled by a stepping motor and

can be equipped with additional devices such as a bar

code scanner, printer, or checking units

- User-friendly touch screen operation

- Easily exchangeable size parts allow for various

container sizes

- Containers are discharged into trays

- Station can be equipped with a hot-foil, thermal

transfer, laser, or ink jet printer

- Horizontal and vertical adjustments of the printer adapt

to different print areas

- Rubber roller dispensing station ensures smooth label

application on containers

Type 603

The Type 603 is a fully automatic labeling machine designed for applying self-adhesive labels to vials, cartridges, ampoules, and other special containers. It can function as a stand-alone labeler or be integrated into a fully automatic production line.

Key Features

- Outputs up to 36,000 containers per hour

- Quick, tool-free size part changes

- Easy accessibility to all working stations

- Smooth, continuous container transport

- Automatic rejection of nonconforming objects

- Safety system ensures user protection

- User-friendly touch screen operation

- Integrated electronic control cabinet in the machine

base

- Can be equipped with a bar code scanner, vision

system, and various printer types

Type 604

The Type 604 is a fully automatic, linear machine designed to apply self-adhesive labels to bottles. Labels are printed by a hot foil, thermal transfer, or laser printer and then transferred to the labeling station. Containers are fed from an upstream machine by a rotary table or conveyor to complete the label application process.

Key Features

- Outputs up to 12,000 containers per hour

- Highly flexible and compact design

- Label dispenser unit with servo technology

- Automatic speed synchronization

- User-friendly touch screen operation and system

control via PLC

- Accurate placement of labels on containers

- Options available for barcode scanner, label position

and presence check, and printer

Type 607

The Type 607 is a compact machine that combines high-speed plunger rod insertion, backstop assembly, and labeling of syringes. It can process various types and sizes of syringes, plunger rods, and backstops with the use of interchangeable size parts.

Key Features

- Outputs up to 24,000 syringes per hour

- Servo-controlled main drive and rotation motion of the

syringe produce precise and constantly monitored

torque

- Rotary movement of syringes to ensure smooth

positioning

- Torque feedback allowing for automatic adjustment of

insertion

- Integration of hot foil, inkjet, or laser printers

- Vision system for validating correct label information

- Automatic rejection of non-conforming containers

- Can be used as a stand-alone machine or integrated

into a processing line

Series 700

Type 703

The Type 703 tray loader is a precise and compact solution for loading containers into trays. It can handle various sizes of vials, bottles, syringes, ampoules, cartridges, and other stable standing containers. A fully integrated camera system ensures all quality standards are met.

Key Features

- Outputs up to 36,000 objects per hour

- Adjustable infeed guides to process various container

sizes

- Transport of containers to the loading station via servo

driven transport belt

- Configurable for various types of trays (e.g., stainless

steel, cardboard, 3-sided trays)

- Camera verification system

- Automatic rejection of non-conforming objects

Type 728

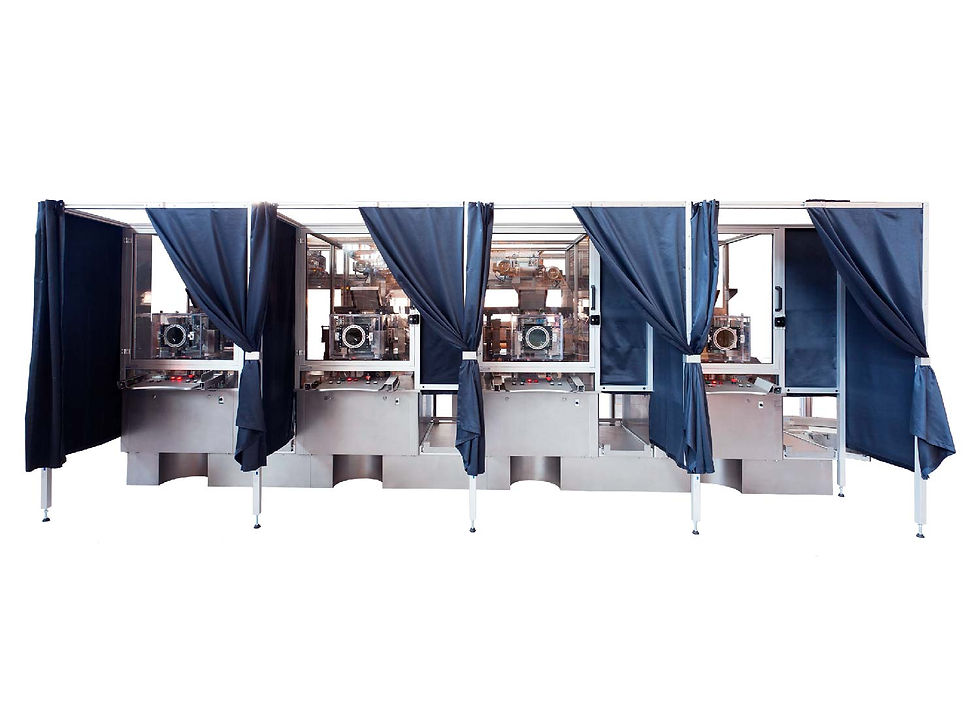

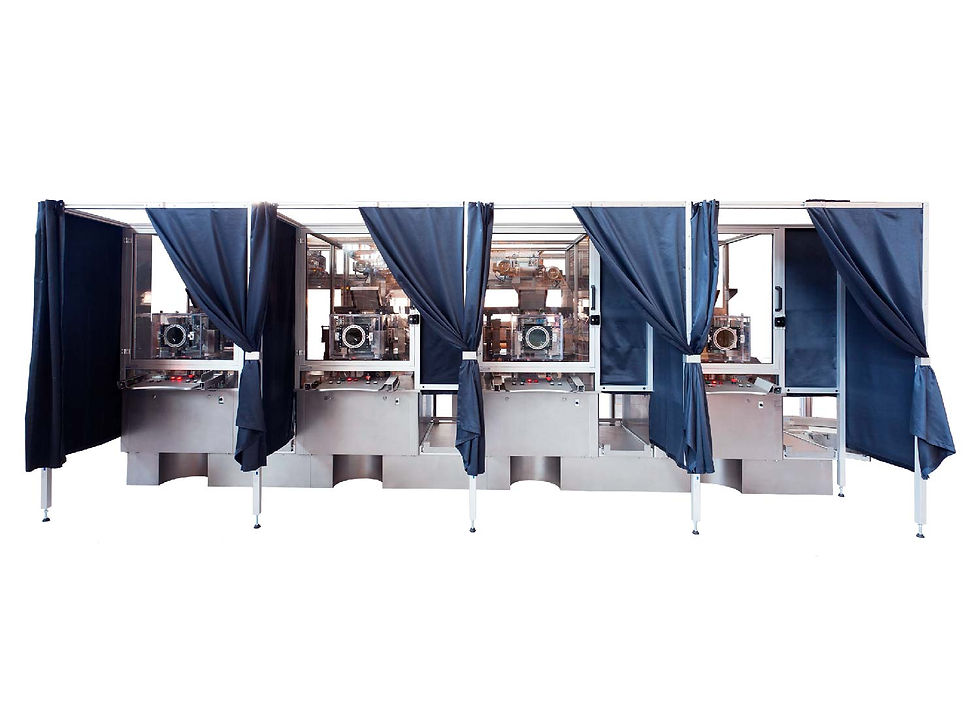

The Type 728 is a visual inspection machine for bags utilizing the Tyndall effect. Bags are fed from an upstream conveyor into the inspection station, where they are analyzed multiple times by rotation. Non-conforming bags are rejected and not mixed with good bags. Upgradable features include conveyor belt infeed, report data printing, dark protection curtains, and spare/wear parts.

Key Features

- Non-conforming bags are rejected from the machine

- Upgradable features include conveyor belt infeed,

report data printing, dark protection curtains, and

spare/wear parts

Machines by Series

Series 300

Type 303/304/305

Key Features

- Outputs up to 9,000 containers per

hour

- Constructed from high-grade

stainless steel and pharmaceutical

grade plastics

- Smooth container handling with

coated grippers

- Optional cost-effective WFI

recycling unit

- Compatibility with various cleaning

agents

- Energy-efficient cleaning needle

design

- Needle movement ensures thorough

cleaning of the entire container

interior

- No glass-to-glass contact during

cleaning cycles

- Optional siliconization with servo

controlled needle movement for

customized silicone patterns

The Type 303/304/305 machines are designed to wash vials, syringes, cartridges, and ampoules. They clean and dry both the inside and outside of the containers, achieving up to a 3-log reduction in contaminants.

Type 306

Key Features

- Outputs up to 1,500 containers per

hour

- Manual loading

- Cleans the inside and outside of the

containers

- Quick size changes

- Intermittent spray of media

synchronizes with the transport

system

- Up to 12 stations with 3 different

cleaning media

- Optional recycling station

The Type 306 is a semi-automatic washing machine designed for smaller scale operations, suitable for ampoules, vials, syringes, bottles, and cartridges.

Type 308

Key Features

- Outputs up to 36,000 containers per

hour

- Containers are fed automatically

from an upstream machine or

manually from trays

- Ultrasonic bath for pre-cleaning of

the objects

- No glass-to-glass contact using

coated container grippers

- Specialized cleaning needles

designed to improve energy

efficiency

- Servo motors positioned along the

line guarantee the alignment of the

containers with the washing and

drying needles

The Type 308 is a high-speed machine designed to wash ampoules, cartridges, syringes, and vials. Featuring an innovative balcony design, it allows operators to maintain visual contact with the process. Fully customizable, it offers modules for inside and outside cleaning, inner and outer blow drying, siliconizing, tip cap or needle shield application, and the use of various cleaning agents.

Type 309

Key Features

- Outputs up to 21,000 containers per

hour

- Flexible and compact design allows

for customized cleaning cycles

- Easy access to the cleaning stations

and for size changes

- Quick and easy size changeovers to

process container sizes up to 95 mm

in diameter and 180 mm in height

- Specialized cleaning needles

designed for ideal results and

improved energy efficiency

- Sterile hot air blow drying

parameters are adjustable via the

operator interface terminal

- Optional recycling station, Type 705,

provides cost efficient

reconditioning of used cleaning

agents

The Type 309 machine is a fully automatic, continuous washing system designed for the external cleaning of ampoules, vials, and bottles. It washes, rinses, and dries the external surfaces of the containers, which are then discharged into trays or sent to downstream processing.

Type 401-40X

Key Features

- Outputs up to 610 kg per hour

- Air convection pre-heating and

sterilizing zone for energy efficiency

and gentle heating of the containers

- Containers are fed automatically

from an upstream machine or

manually using trays

- Temperature and differential

pressure indicators ensure ideal and

repeatable machine settings

- Temperature distribution is achieved

by multiple control sensors

- PLC for system control and

monitoring of relevant data

- Servo-controlled baffles aid in cross

flow regulation

The Type 400 series machines offer hot air sterilization for glass ampoules, vials, syringes, and cartridges. The depyrogenation process is divided into three main zones: 1) Pre-Heating, 2) Depyrogenation, and 3) Cooling. These machines can be seamlessly integrated into downstream processing.

Type 302

Key Features

- Outputs up to 24,000 containers per

hour

- Smooth container handling with

coated grippers

- Infeed options from trays or an

upstream machine

- Available ultrasonic bath and

recycling station

- Optional water heating up to 85°C /

185°F

The Type 302 is a rotary washing system designed for cleaning ampoules, bottles, cartridges, vials, and various other containers.

Type 411

Key Features

- Machine designed as a pass-through

into a cleanroom or isolator

- Components are placed into the

chamber by an operator or robotic

arm, and the door is closed to

contain the process

- Complete cycle (loading, exposure,

and unloading) decontaminates the

entire interior of the unit and

container surfaces within 20-60

seconds

- Components are removed and ready

for the next processing stage

- 100% verification on every cycle

- Available as a stand-alone or in-line

machine

The Type 411, Puv-A-Tech™, is an enclosed sterile transfer chamber utilizing pulsed ultraviolet radiation light to decontaminate outer surfaces. This technology achieves up to a 6-log reduction within 5-30 seconds of exposure time.

Type 502/503

Key Features

- Outputs up to 6,000 containers per

hour

- A transport star wheel provides

smooth and continuous transfer of

the objects to the working stations

- Two-piece, valveless dosing pumps

provide precise dosing with filling

accuracy up to +/- 0.05%

- The containers are continually

rotated to minimize foaming of the

product and ensure an evenly

heated ampoule stem, leaving a

perfect dome

- Vials are closed with rubber

stoppers, fed from a vibrating bowl

- Optimized for use under laminar

flow, RABS, or isolator

- The machines can be used as stand

alone units or integrated into a

production line

The Type 502/503 machines combine the filling and closing of ampoules into one single compact unit.

Series 400

Type 504-506

Key Features

- Outputs up to 24,000 containers per

hour

- Rotary-style machine provides

smooth and gentle continuous

transport of the objects

- System control via PLC

- User-friendly touch screen

operation

- Rotation of the object minimizes

foaming of the product and ensures

an evenly heated ampoule stem,

leaving a perfect dome

The Type 504/505/506 machines are designed for filling and closing both open and pre-sealed ampoules. Their design enables quick and easy changeover from ampoules to vials.

Type 515

Key Features

- Outputs up to 3,600 containers per

hour

- Liquid filling

- Highly flexible and compact design

- Containers are transported into a

star wheel that moves them to

different processing stations

- Filling needles are controlled by a

servo drive for fast and accurate

dosing

- Ultra-high filling accuracy

- Stoppering is fed through a sorting

bowl, picked up by a vacuum tool,

and precisely inserted

- Few size parts, quick changeover

from vials to syringes

- Integrated inspection system

- Laminar flow and/or isolator friendly

design

- Can be used as a stand-alone

machine or integrated into a

complete processing line

The Type 515 is a filling and closing machine designed for vials and syringes. Optimized for use under laminar flow and constructed from high-grade stainless steel, this machine ensures optimum hygienic performance.

Type 515 Plunger

Rod Assembly

Key Features

- Outputs up to 2,400 syringes per

hour

- Compact machine design with

integrated control cabinet

- High precision plunger rod insertion

- Monitored torque for ideal closing

results

- Camera inspection checks for

proper plunger rod and backstop

placement

- Optional labeling station available

The Type 515 combines high-speed plunger rod insertion and labeling of syringes in a single unit. At the heart of the machine is an automated transport star wheel that moves products through four different stations, enabling the assembly of up to 40 syringes per minute. At the first station, a pneumatically actuated gripper assembly picks up a plunger rod from the end of the vibratory track and uses a 2-axis robotic arm to thread it into a syringe. At the second station, backstops are carefully placed on the flange of each syringe. The third and fourth stations check for the presence of the plunger rod and backstop.

Type 529

Key Features

- Available in tabletop, dual, semi

automated conveyor, and fully

automatic versions

- Ideal for lab trials (1 filling head) and

production (2-4 filling heads)

- Peristaltic or mass flow filling

method options

- Attached flow regulator for high

filling accuracy

- Automatically cuts pre-sealed tubes

for filling

- Stoppering and heat/RF/ultrasonic

sealing

- Manual or conveyor belt transport

system

- Integrated closing system

eliminates product contamination

- Compatible with Laminar Flow and

light curtain systems

The Type 529 semi-automatic filling and closing machine for flexible bags sets new standards in the pharmaceutical market. It is capable of processing all bag types (EVA, PVC, PP) with fill volumes ranging from 50 mL to 5 L.

Type 534

Key Features

- Outputs up to 9,000 containers per

hour

- Good accessibility to all

workstations with inline design

- Adjustable walking beam transport

for different container sizes

- Servo-controlled filling needles for

precise filling tolerance up to

+/-0.05%

- Up to 100% in-process control

verification

- Sorting bowls for closures such as

stoppers and caps

- Vacuum-activated placement of

stoppers into vials

- Torque-monitored crimp capping

- Separate container reject and

discharge lanes

- Compatible with RABS, Laminar

Flow, and/or isolator systems

The Type 534 is an automated filling and closing machine designed for vials, bottles, and other free-standing containers. Its modular design allows for easy customization to meet specific customer requirements.

Type 535

Key Features

- Outputs up to 4,600 containers per

hour

- Manual nest loading and unloading

- Turn table in-feed and out-feed

- Rotary piston pump, peristaltic

pump, or time pressure filling

options

- 6-Axis clean room robot or X-Y

transport system

- Sorting bowls for closures

- Filling and closing under vacuum to

reduce contamination and bubble

formation

- Compact machine design with

integrated Laminar Flow

- Machine guarding for optimum user

safety

The Type 535 machine is designed to fill and close nested vials, syringes, and other nested containers. It is the ideal solution for manufacturers seeking to automate and/or validate the filling of products in clinical trials or during the development phase.

Type 543

Key Features

- Outputs up to 10,000 containers per

hour

- Rotary piston pump, peristaltic

pump, or time-pressure dosing

options

- Customized stoppering station with

vacuum assist

- Direct in-line verification with

camera system

- All parts in contact with the product

can be easily disassembled and

sterilized

- Quick and easy size changeovers

- Containers are transported

separately in individual holders,

which can be quickly changed for

different size containers

The Type 543 filling and closing machine is designed to process vials, syringes, and cartridges with either intermittent or continuous motion throughout the machine. Its modular design allows for easy adaptation to customer-specific requirements.

Type 550

Key Features

- Outputs up to 36,000 containers per

hour

- Processes standard and freeze

dried rubber stoppers

- Best suited for through-the-wall

installations

- Adjustable main transport system

for quick and easy size changeovers

- Containers are separated and

individually fed to the main

transport system

- Optional pre- and post-gassing

available

- Integrated inspection system to

reject faulty containers

- Precision force control for crimping

and integrated visual inspection

system ensures proper sealing

- Balcony design provides optimized

laminar flow friendly operation

inside a Class A clean room and can

be directly combined with an

isolator or a rapid access barrier

system (RABS)

The Type 550 machine features a high-speed, continuous motion balcony design for the filling and closing of vials and cartridges. Its servo drive technology ensures maximum versatility and repeatability.

Type 570

Key Features

- Flexible pick & place modular

platform

- Automatic robot technology for all

processing

- Compatible with isolator and/or

laminar flow systems

- Compatible with lyophilization

transfer chambers

- Robot fills and stoppers nested

containers

- Filling by peristaltic pump with

disposable fill kits

- Custom nest holder for easy

transfer of nested containers in and

out of the processing system

- Robot picks up a bag, inserts the

open tube into the filling needle, and

then seals the tube

The Type 570, Vers-A-Tech™ is a semi- or fully-automatic machine designed to accelerate the packaging of Cell & Gene Therapy products, handling both bags and nested containers on a single platform.

Type 601/602

Key Features

- Outputs up to 24,000 containers per

hour

- Containers are automatically fed

from an upstream machine or

manually using trays

- Individual transport of containers to

the labeling station by a star wheel

- Transport wheel designed with

pockets for safe and gentle handling

of containers

- Precision servo control label

dispenser for self adhesive labels

- Label dispenser is adjustable for

different sizes

- Label dispenser is controlled by a

stepping motor and can be

equipped with additional devices

such as a bar code scanner, printer,

or checking units

- User-friendly touch screen

operation

- Easily exchangeable size parts allow

for various container sizes

- Containers are discharged into trays

- Station can be equipped with a hot

foil, thermal transfer, laser, or ink jet

printer

- Horizontal and vertical adjustments

of the printer adapt to different print

areas

- Rubber roller dispensing station

ensures smooth label application on

containers

The Type 601-602 machines are compact, fully automatic systems designed for printing and applying self-adhesive labels to vials, bottles, syringes, ampoules, and cartridges. These continuous motion labelers can be integrated into a production line or operated as stand-alone machines.

Series 600

Type 603

Key Features

- Outputs up to 36,000 containers per

hour

- Quick, tool-free size part changes

- Easy accessibility to all working

stations

- Smooth, continuous container

transport

- Automatic rejection of

nonconforming objects

- Safety system ensures user

protection

- User-friendly touch screen

operation

- Integrated electronic control cabinet

in the machine base

- Can be equipped with a bar code

scanner, vision system, and various

printer types

The Type 603 is a fully automatic labeling machine designed for applying self-adhesive labels to vials, cartridges, ampoules, and other special containers. It can function as a stand-alone labeler or be integrated into a fully automatic production line.

Type 604

Key Features

- Outputs up to 12,000 containers per

hour

- Highly flexible and compact design

- Label dispenser unit with servo

technology

- Automatic speed synchronization

- User-friendly touch screen

operation and system control via

PLC

- Accurate placement of labels on

containers

- Options available for barcode

scanner, label position and presence

check, and printer

The Type 604 is a fully automatic, linear machine designed to apply self-adhesive labels to bottles. Labels are printed by a hot foil, thermal transfer, or laser printer and then transferred to the labeling station. Containers are fed from an upstream machine by a rotary table or conveyor to complete the label application process.

Type 607

Key Features

- Outputs up to 24,000 syringes per

hour

- Servo-controlled main drive and

rotation motion of the syringe

produce precise and constantly

monitored torque

- Rotary movement of syringes to

ensure smooth positioning

- Torque feedback allowing for

automatic adjustment of insertion

- Integration of hot foil, inkjet, or laser

printers

- Vision system for validating correct

label information

- Automatic rejection of non

conforming containers

- Can be used as a stand-alone

machine or integrate into a

processing line

The Type 607 is a compact machine that combines high-speed plunger rod insertion, backstop assembly, and labeling of syringes. It can process various types and sizes of syringes, plunger rods, and backstops with the use of interchangeable size parts.

Type 703

Key Features

- Outputs up to 36,000 objects per

hour

- Adjustable infeed guides to process

various container sizes

- Transport of containers to the

loading station via servo driven

transport belt

- Configurable for various types of

trays (e.g., stainless steel,

cardboard, 3-sided trays)

- Camera verification system

- Automatic rejection of non

conforming objects

The Type 703 tray loader is a precise and compact solution for loading containers into trays. It can handle various sizes of vials, bottles, syringes, ampoules, cartridges, and other stable standing containers. A fully integrated camera system ensures all quality standards are met.

Series 500

Type 728

Key Features

- Non-conforming bags are rejected

from the machine

- Upgradable features include

conveyor belt infeed, report data

printing, dark protection curtains,

and spare/wear parts